Paper mill liquor lines

Customer

Paper Mill in Virginia.

Application

Green liquor piping, white liquor piping, evaporator piping, heat exchangers.

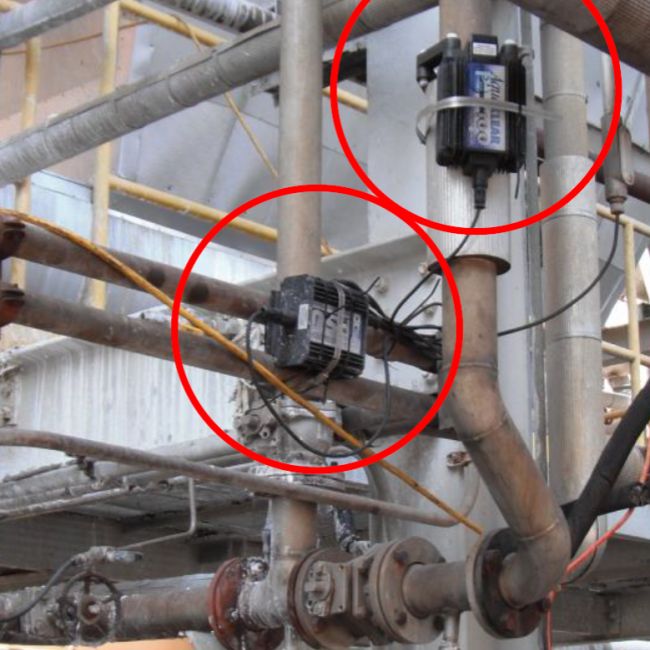

Installed unit

Fifteen HydroFLOW water conditioners in various locations of high mineral concentrations.

Background

One of the byproducts of papermaking is the generation of high concentrations of calcium carbonate, sodium carbonate and sodium sulfate in the process water. Due to the high concentrations of these minerals; scale deposits coat the inside of pipes, pumps and heat exchangers, restricting flow and heat transfer efficiency. Typically, pipes and equipment need to be disassembled and cleaned (by hydro-blasting) approximately every 6 months.

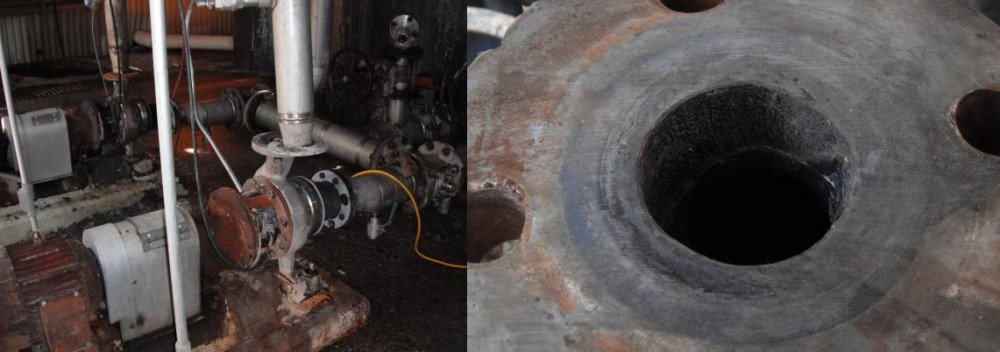

Treated Pump

Treated PumpResults

- The water conditioners kept the pump impeller housings clear of scale build up, improving flow rate and extending pump life.

- The water conditioners have a positive effect on heat exchanger performance by breaking-up the scale deposits on the internal tubes thus increasing heat transfer efficiency.

- The water conditioners kept piping clear of most scale deposits and made existing deposits easy to remove.

- The return on investment, due to decreased maintenance labor and power usage is approximately one year.

For the full case study please click on the PDF.